One of the key aspects of the CRF’s mission is to encourage collaborations between our researchers and the academic and corporate communities, especially to help our partners develop Sandia-based technologies into commercial products that bring value to the larger public. Recently, the CRF recently hosted its first ‘Industry Day,’ an event that brought together manufacturers, end-users, entrepreneurs, and local government and business representatives. The day centered around the “Sandia Cooler,” an innovative new technology developed by researcher Dr. Jeff Koplow. A novel, proprietary air-cooling invention, the Sandia Cooler has the potential to alter the air-cooling landscape dramatically in computing and microelectronics, LEDs/solid-state lighting, HVAC, and other applications, resulting in huge economic and energy savings.

Industry Day had several overlapping purposes:

- To share the Cooler technology and its potential with industry;

- To glean insight from industry about commercialization of this and future technologies;

- To create connections and explore synergies among a diverse group of stakeholders who collectively could take ownership of commercializing the Cooler technology.

“Our primary interest is in getting this technology into the marketplace and making an impact on energy efficiency,” explains Senior Manager Art Pontau. “We do this because we are a national security lab whose mission includes energy and economic security. We want to assure that this technology is successful and making a difference as quickly as possible.”

The Technology

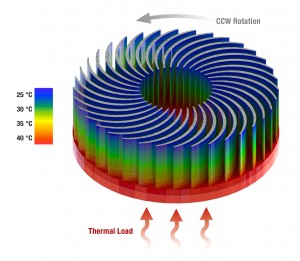

In a conventional heat sink, the heat transfer bottleneck is the boundary layer of “dead air” that clings to the cooling fins. With the Sandia Cooler, heat is efficiently transferred across a narrow air gap from a stationary base to a rotating structure. The normally stagnant boundary layer of air enveloping the cooling fins is subjected to a powerful centrifugal pumping effect, causing the boundary layer thickness to be reduced to a tenth of its normal value. This reduction enables a dramatic improvement in cooling performance within a much smaller package. Additionally, the high-speed rotation of the heat exchanger fins minimizes the problem of heat exchanger fouling. The way the redesigned cooling fins slice through the air greatly improves aerodynamic efficiency, which translates to extremely quiet operation.

The value proposition for the Sandia Cooler, explains Manager Neal Fornaciari, is a dramatic increase in cooling performance without resorting to complex methods such as liquid cooling. The technology generates a significant improvement in cooling performance in a device that is 10 times smaller than the current state-of-the-art, exceptionally quiet, immune to dust fouling, and relatively simple to manufacture.

The Sandia Cooler’s benefits have been verified by lab researchers on a proof-of-concept prototype roughly sized to cool computer CPUs. The technology, says Koplow, shows great potential for personal computer applications and also offers benefits in other applications where thermal management and energy efficiency are important, particularly heating, ventilation, and air-conditioning (HVAC).

The Meeting

A number of established cooling system manufacturers, entrepreneurs potential end users attended Industry Day, along with representatives from the City of Livermore and the Alameda County Small Business Center. Dr. Koplow presented an overview of the Cooler technology and then led visitors to his lab for prototype system demonstrations. The group discussed potential applications for the technology and ideas on enabling a successful commercialization process, and ended with informal networking to explore opportunities surrounding this breakthrough innovation.

Industry Day was very successful, says Ed Noma, who leads business development for the Sandia Cooler. “Bringing this diverse group together, with their different perspectives and relationships to the technology, was very important,” he explains. “We need a critical mass of potential industry partners excited about this technology who will in turn catalyze a broader ecosystem of stakeholders to accelerate the commercialization process.”

Sandia’s work on the cooler technology was funded initially through internal investments. Follow-on funding is also being provided by the Department of Energy’s Office of Building Technologies. Sandia is currently engaged in discussions with companies that have expressed interest in licensing the Sandia Cooler. The Labs welcome communications for any other parties interested in licensing the technology.

Quick Facts

The yearly electricity bill paid by the IT section in the US is ~$7 billion and growing.

An estimated 24% of US electricity consumption comes from cooling equipment such as air conditioners and refrigerators.

“Over the past 40 years the technologies, designs, and performance of air-cooled heat exchangers have remained unchanged. The performance data for today’s state-of-the-art heat exchangers and blowers is, in many cases, based on measurements performed in the 1960s.” [DARPA, 2008]