To meet aggressive national goals for significantly reducing petroleum use and greenhouse gas emissions requires major improvements in all aspects of the nation’s energy use. Combustion processes have historically dominated electrical power production and transportation systems. Despite major advances in improving the efficiency and reducing the costs of alternative energy sources, combustion-based systems are projected to dominate the marketplace for decades. Consequently, these systems need to be optimized for energy efficiency and reduced emissions.

The Exascale Computing Project is structured around providing a combination of first-principles Direct Numerical Simulation (DNS) and near first-principles [Direct Numerical Simulation/Large Eddy Simulation (DNS/LES) hybrids] simulations to advance understanding of fundamental turbulence-chemistry interactions in device-relevant conditions. The exascale motivating problem is to perform high-fidelity simulations of the relevant processes in a low-temperature reactivity-controlled compression ignition (RCCI) internal combustion engine. The relevant processes include turbulence, mixing, spray vaporization, low-temperature ignition, flame propagation, and soot/radiation. RCCI is thermodynamically favorable relative to existing engines and hence holds the promise of groundbreaking efficiencies while operating in a regime that limits pollutant formation. The roadmap towards this exascale-era motivating problem includes simulation of a multi-injection low-temperature diesel jet into an open domain with a large alkane fuel undergoing two-stage ignition processes, simulations of dilute spray evaporation and mixing, and simulation of multi-injection with fuels of varying reactivity in a geometry that influences the mixing field. The latter of these simulations forms the challenge problem to demonstrate new exascale capability on Frontier at the OLCF.

The motivating problem that anchors the team’s proposed development is a sufficiently realistic simulation of the in-cylinder processes in an internal combustion engine utilizing low-temperature combustion (LTC), for which RCCI is the exemplar. The enabled exascale-era simulations will address key scientific questions regarding mixture formation effects, multi-stage ignition of a diesel surrogate fuel, lifted flame stabilization, jet re-entrainment affected by cylinder-wall geometry, and emissions. The simulation will account for isentropic compression, subsequent injection of the high-reactivity fuel, and combustion processes in a compression ignition engine. Necessary physics include gas compression and models of fuel injection process, spray vaporization (injection of liquid fuel sprays into high-pressure conditions), mixing, and combustion processes: autoignition, flame propagation, soot and thermal radiation, all in a non-trivial engine geometry. The scenario involves kinetically controlled processes in turbulent combustion including ignition, extinction, and emissions. The application for this project, Pele, implements a hybrid LES/DNS approach in both the compressible and low-Mach limits where, using the machinery of adaptive mesh refinement (AMR), the team will refine to the DNS limit where necessary to capture turbulence/chemistry interactions while restricting resolution to that required for a high-fidelity LES model far from the flame.

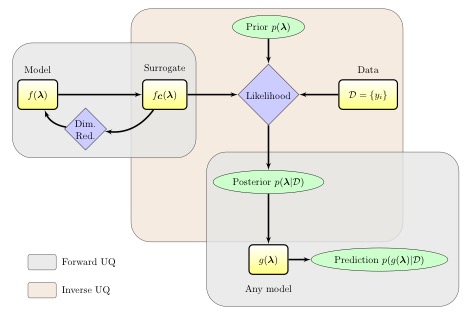

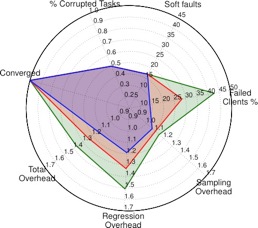

Progress is necessary on several challenging, but tractable, fronts. Existing simulation tools are being evolved to perform well on exascale architectures, maintaining existing physics capability along with performance portability. Algorithmic and implementation issues involve new memory management and data layouts that respect memory systems of emerging architectures including graphics processing units (GPU’s), new load balancing and communication strategies, communication avoiding linear solvers that trade communication for computation, strategies for asynchronous task execution, and in situ analytics approaches. Improved modeling of physical processes is also needed. The fidelity of physics models that are tractable at the exascale greatly exceeds that of current petascale codes. High-fidelity physical models for non-ideal fluid behavior, sprays, soot, and radiation, as well as non-trivial geometry, are being implemented and provide a significant improvement in the realism of combustion simulations as typified by the target problem. Further, at the low temperature conditions of relevance to RCCI, combustion is extremely sensitive to the autoignition process and consequently to the detailed mechanism of multi-component fuel chemistry. We plan to automate theoretically derived, UQ driven, chemical mechanism generation to enable the use of high-fidelity drop-in chemical models in our DNS/LES. Lastly, advances in numerical algorithms are being used to treat new and improved physical process models, optimize linear solvers to obtain good convergence rates with realistic geometry, improve coupling of the various physical processes to expose parallelism while maintaining a high order of accuracy, and optimize solution algorithms to handle the effects of non-ideal chemistry.

PI: Jackie Chen