Fuel spray injection will be a key element for enabling high-efficiency, low-emission engines of the future. Understanding the spray combustion process is critical, however, investigating engine combustion processes is challenging due to factors affecting the in-cylinder environment where mixing with fuel sprays occurs. The temperature, pressure, density, and composition of the in-cylinder gases and the fuel-injector conditions have a direct effect on combustion and emission-formation processes.

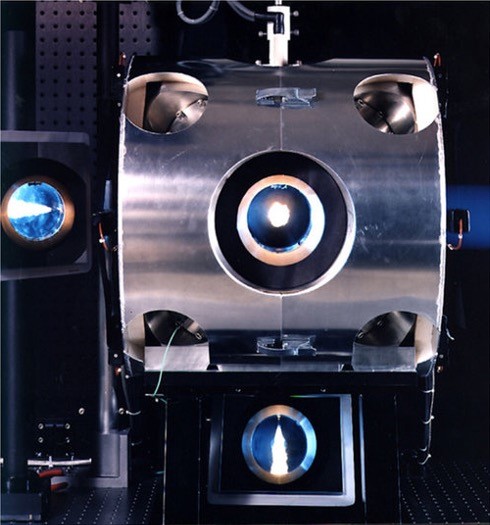

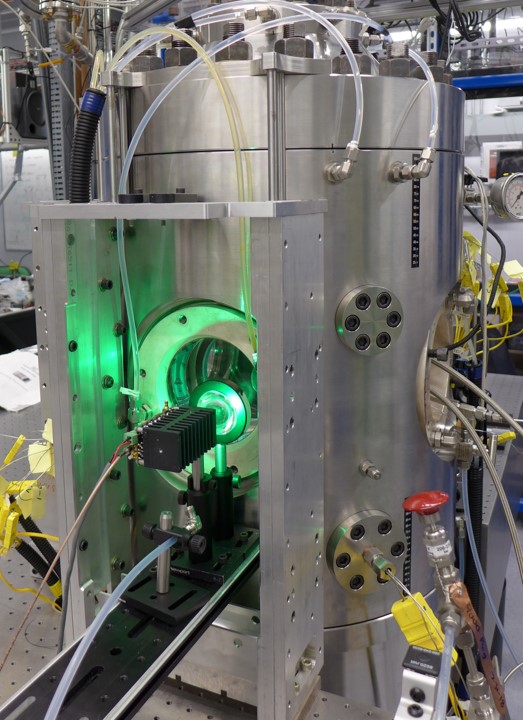

Unique installations available in the CRF’s Spray Combustion Laboratories can simulate a wide range of ambient (charge gas) environments at the time of fuel injection, allowing researchers to assess the effect of each variable with more control than can be achieved in an engine. There are two high-pressure and high-temperature optically accessible chambers at the CRF: (1) A constant-volume vessel and (2) a constant-flow chamber.

Facility Capabilities

| Parameters | Constant-volume vessel | Constant-flow chamber |

| Temperature range [K] | 400 – 1700 | 300 – 1100 |

| Pressure range [bar] | 1 – 350 | < 1 – 150 |

| O2 concentration range [%] | 0 – 21 | |

| Repetition rate | Every 5 min | Every 1-3 s |

CRF researchers use advanced laser and optical diagnostics to study the fundamental spray and combustion processes. Data obtained in these facilities are used to provide detailed understanding of the spray and combustion phenomena at relevant engine conditions. Beyond gaining fundamental knowledge about these processes, we use the information to improve computational fluid dynamic models, which in turn are used to optimize engine designs.

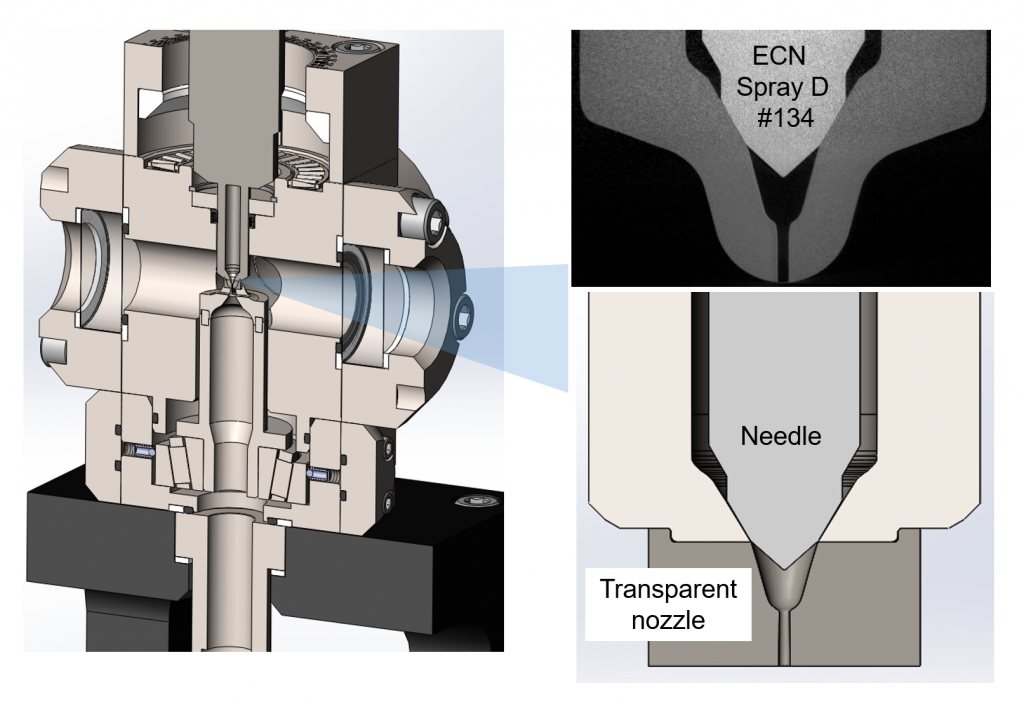

Understanding of sprays and injector flow is enhanced by using a unique transparent nozzle research vessel. As shown below, a regular diesel or gasoline injector is ground flat below the needle sealing surface and replaced with a transparent nozzle (acrylic or other transparent material). The transparent injector nozzles are manufactured with real size and shape compared to the original metal injector. The nozzles are mounted and sealed inside a small, pressurized vessel and operated at realistic injection pressures (to 1000 bar). High-speed long-distance microscopy is applied to visualize the flow, cavitation, and gas exchange within the hole and sac.

The activities of the Spray Combustion Laboratories as well as the large number of international partners and collaborators led to the creation of the Engine Combustion Network (ECN). Started in 2009, the ECN is an international collaboration among experimental and computational researchers in engine combustion with the following objectives:

- Establish an internet library of well-documented experiments that are appropriate for model validation and the advancement of scientific understanding of combustion at conditions specific to engines

- Provide a framework for collaborative comparisons of measured and modeled results

- Identify priorities for further experimental and computational research

The focus of the ECN has been targeted diesel and gasoline sprays, and over 20 institutes contributed to the group with advanced experimental work. More than 30 institutions have contributed to the simulation effort taking place at the ECN. It is also important to activities of the ECN evolve, changing with the scientific research landscape. Future work is likely to include engine datasets, as well as targeted research oriented toward other combustion-based power generation and transportation systems.

The Spray Combustion Laboratories are also the lead organizers for the Spray Combustion Consortium (SCC). The SCC is an industry-funded activity aiming to improve engine combustion system design and optimization tools. Formed in late 2015, this industry steering committee guides SCC spray research at Sandia National Laboratories, Argonne National Laboratory, and the University of Massachusetts.

PIs: Lyle Pickett, Julien Manin