The Heavy-Duty Engine Combustion and Fuel Effects Laboratory centers around a modern 1.7-liter, single-cylinder diesel engine that has been modified to provide extensive optical access to the combustion chamber. Researchers apply advanced imaging, laser-based, and conventional diagnostics to gain a fundamental understanding of the detailed in-cylinder mixing and combustion processes that govern engine efficiency, emissions, and performance. The results facilitate stakeholder collaboration to achieve practical, clean, and sustainable engines and fuels for the future.

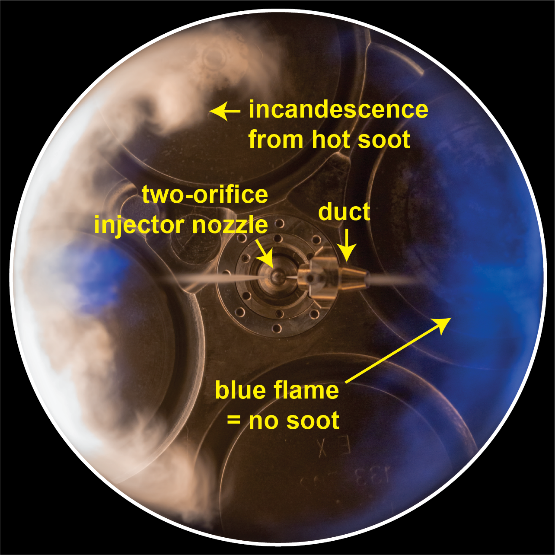

The current research focus is on ducted fuel injection (DFI) with sustainable fuels. DFI is a new and conceptually simple mechanical technology to enhance the preparation of fuel/charge-gas mixtures within the combustion chambers of engines, with the goal of dramatically attenuating soot formation. Based loosely on the concept of the Bunsen burner, DFI involves injecting fuel along the axis of a small cylindrical duct within the combustion chamber to achieve more-complete local premixing at or near the end of the duct where ignition occurs. Although DFI is in a relatively early stage of development, it has been shown to profoundly curtail soot formation in optical-engine experiments.

When used with today’s diesel fuel, DFI has been found to curtail hot, in-cylinder soot by ~10X relative to conventional diesel combustion. When used with sustainable, oxygenated fuels, DFI can provide an additional ~10X soot-reduction benefit, resulting in an overall soot reduction of ~100X, and providing a market incentive for cleaner, sustainable fuels. Furthermore, the observed soot reductions can be achieved regardless of the intake-mixture oxygen concentration, enabling exhaust-gas recirculation to be used for simultaneous, cost-effective reductions of nitrogen-oxide emissions by 10X or more.

Current activities focus on elucidating the effects of duct geometric parameters and fuel properties on DFI performance, with the goal of advancing the technology for deployment in production engines with low-net-carbon fuels.

Figure 1 Conventional diesel combustion (left spray) and ducted fuel injection (DFI, right spray) as viewed through the piston window in the optical engine. The whitish crescent on the left side is produced by incandescence from hot soot. The crescent on the right side is blue because the DFI combustion on this side of the chamber produces little to no soot.