Aggressive DOE Vehicle Technologies Program (VTP) gasoline engine fuel-economy and pollutant- emission targets can be met through some combination of reduced heat transfer, lower throttling losses, shorter combustion durations, lower combustion temperatures, improved mixture preparation, and higher compression ratios. Charge dilution by air or exhaust gas recirculation (EGR) is the most common method to achieve many of these benefits for low-power conditions, but increased dilution is offset by poorer combustion stability.

A primary limitation of higher dilution levels is a slow, early burning rate when using conventional inductor coil ignition systems. Consequently, advanced ignition technologies are needed to produce larger and more energetic ignition volumes, while still performing well under elevated cylinder densities and charge motions. Ignition systems may also be an important source of radicals and heat, which are then used to tailor gasoline reactivity for advanced compression ignition (ACI) strategies. However, we currently lack foundational understanding of igniter mechanisms for new technologies, which inhibits the development of production-ready systems.

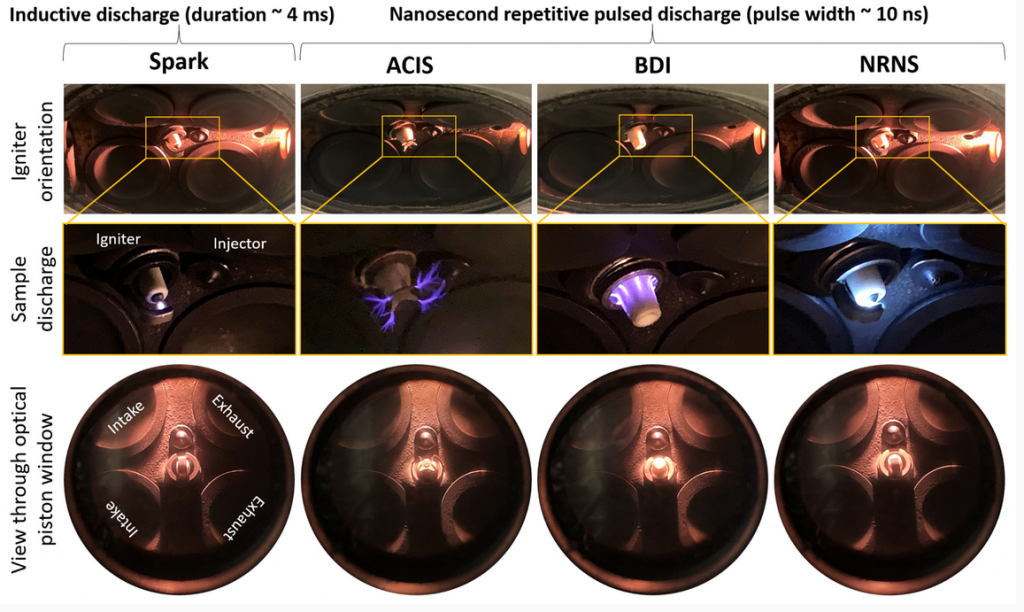

Gasoline Combustion Fundamentals Laboratory researchers seek to improve understanding of ignition physical and chemical processes and to use this information to develop more reliable engine simulation sub-models. Relevant ignition processes include plasma formation from deposited electrical energy, plasma-to-flame transition, and flame kernel development. Experiments are performed in a single-cylinder research engine and ignition test vessels, all containing suitable optical access. In situ optical diagnostics and ex situ gas sampling measurements elucidate important ignition process details.