Capturing turbulence–flame interaction structure and studying time–history effects requires high-speed volumetric measurements performed at repetition rates sufficiently fast to resolve the relevant flow time scales. Advances in the CRF’s imaging diagnostic capabilities are overcoming these challenges to provide a more complete picture of the structure and dynamics of turbulence–flame interactions.

The Advanced Imaging Laboratory has developed the capability for multi-kHz volumetric velocity-field measurements in flames. This capability is particularly valuable for studying fluid-dynamic strain field evolution, which plays a central role in turbulence–flame interactions. Jonathan Frank and Bruno Coriton, in collaboration with CRF visitor Adam Steinberg of the University of Toronto, recently demonstrated high-repetition-rate tomographic particle image velocimetry (TPIV) feasibility for measuring the dynamics of flow-flame interactions in lifted and burner-stabilized jet flames.

The TPIV technique provides volumetric, three-component velocity-field measurements and enables access to the complete velocity-gradient tensor, which serves as the basis for determining key fluid-dynamic quantities, such as the divergence, vorticity, principal strain-rate components, and tensor invariants. (In contrast, 2-D PIV techniques provide incomplete or biased measurements of these quantities in the presence of 3-D flow structures.) Volumetric three-component velocity data are critical for the proper interpretation and analysis of high-speed imaging measurements in turbulent flows because 3-D motion can complicate temporal data-sequence interpretation. However, high-speed TPIV measurements in turbulent flames are complicated by several factors: significant variations in particle-seeding density, imaging noise, beam steering from the index-of-refraction gradients, and the requirements for high framing rates.

Experimental Method

A new experimental configuration in the Advanced Imaging Laboratory combines high-repetition-rate TPIV and hydroxyl (OH) laser-induced fluorescence (LIF) imaging (shown in Figure 1a) to improve turbulent-flame dynamics analysis. For the TPIV measurements, the particle-laden flow field is illuminated by a several-millimeters-thick laser sheet from a high-repetition pulsed laser. Laser light scattered by submicron aluminum oxide particles is simultaneously imaged onto four high-speed complementary metal-oxide semiconductor (CMOS) cameras with different viewing angles.

Each camera captures each laser pulse’s particle scattering on a single frame. The fields of view from the different cameras are carefully registered using a reference target, and a tomographic reconstruction of the 3-D particle field is performed using a multiplicative algebraic reconstruction tomography (MART) algorithm. Interframe particle displacements are determined by performing multiple-pass cross-correlation analysis using a final interrogation region size of 24 × 24 × 24 voxels (360 × 360 × 360 µm3), yielding more than 900,000 vectors in the probe volume for 10-kHz measurements. Figure 1b shows a single-shot velocity-field measurement at the base of a lifted dimethyl-ether (DME) jet flame.

Structure of Strain Rate Field in Turbulent Jet Flames and Nonreacting Jets

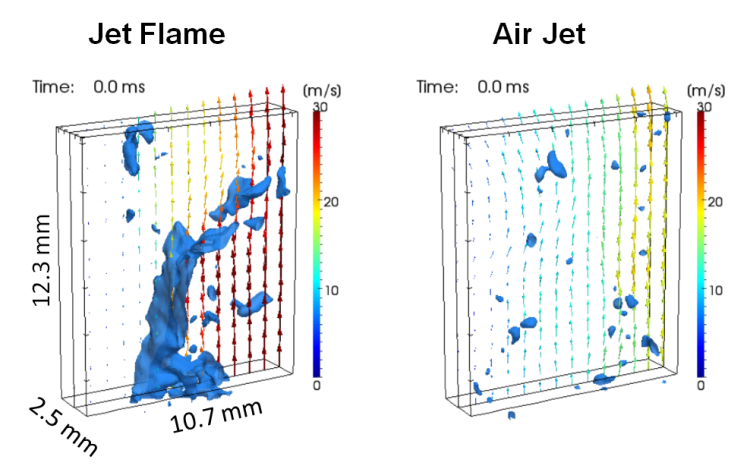

A comparison of 10-kHz TPIV measurements in a turbulent jet flame and a nonreacting air jet reveals the effects of heat release on the structure of the strain-rate field, as shown in Figure 2. In the flame, the isosurfaces of the strain rate norm, |s|, form elongated structures that are concentrated in the shear layer and span a large portion of the probe volume. In contrast, the air jet has smaller structures distributed over a broader region of the jet flow. In both cases, these high strain-rate regions are temporally intermittent, as seen in the movie sequences.

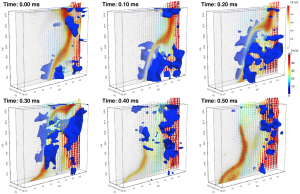

In the flame, the bursts of high strain-rate regions can lead to localized extinction. The measurement sequence in Figure 3 shows the temporal evolution of the velocity, compressive principal strain rate, and OH-LIF fields during a localized extinction event. The velocity and OH-LIF signal are displayed in the central plane, and the compressive strain rate, Γ0, is represented by blue isosurfaces at Γ0 = –15 × 103 s–1. The onset of extinction occurs at time t = 0.20 ms and is identified by the formation of a discontinuity in the contour of the OH-LIF signal.

The image sequence shows large coherent structures with high compressive strain rates in the localized extinction region. These structures remain coherent and closely coupled to the reaction zone until extinction occurs. As the flame approaches extinction, the high-temperature reaction zone becomes thinner. Once the flame is locally quenched, the strain rate decreases, and the large coherent structures break apart. The residence time of the extinguished region within the probe volume is ~0.5 ms, which is too short to capture a subsequent reignition.

Strain-induced localized extinction is a key process in turbulent combustion that affects flame stability, emissions, and the operating conditions of practical combustion devices. The ability to capture the flow field’s temporal evolution in 3-D during localized extinction is an essential tool for understanding turbulent combustion’s complex dynamics. Ongoing efforts are using this new diagnostic capability to investigate the dynamics of the vorticity and strain fields in turbulent flames with localized extinction.